Short-Wave Infrared Camera

Semiconductor testing:

Short-wave infrared cameras are regarded as valuable tools in semiconductor testing. Thanks to their ability to penetrate silicon and other semiconductor materials, they can perform operations such as raw material silicon wafer inspection, die defect detection, and edge position bonding inspection. These capabilities effectively increase semiconductor manufacturing yields, optimize processes, and enhance overall efficiency.

Silicon wafer inspection

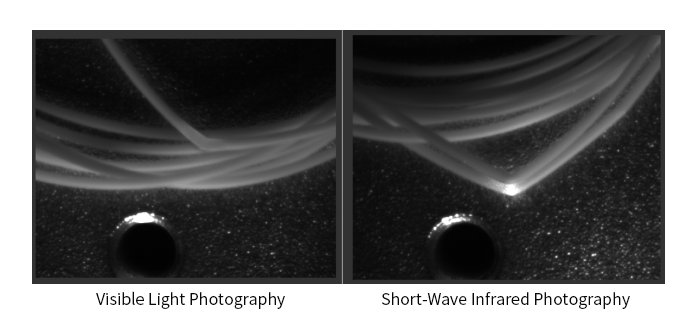

Fiber optic communication:

Optical fiber, as the main transmission medium in modern communication networks, its reliability is directly related to the stability of the entire network. Whether in fiber optic communication or the production and manufacturing of fiber lasers, timely and comprehensive testing of optical fibers is essential. Short-wave infrared cameras can effectively and intuitively detect fiber breakpoints and locate faults, helping to ensure the overall performance and quality of fiber optic systems. Combined with the calibration of software and algorithms, quantitative measurement of light leakage intensity can be achieved

Fiber optic breakpoint detection

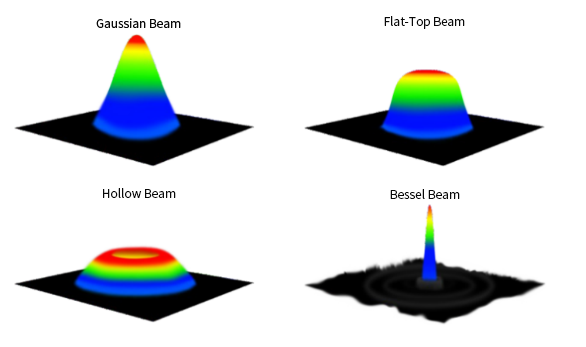

Laser processing:

The core component of a camera-based beam profiler is the short-wave infrared camera. Short-wave infrared cameras can perform real-time 2D and 3D display and measurement of beam shape, size, and spot energy distribution within the wide spectral range of 400-1700nm. They are widely used in laser processing, cutting, and additive manufacturing.

Spot testing

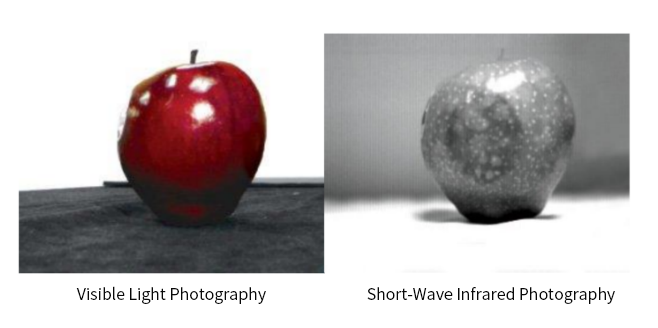

Agricultural product sorting:

Water has the property of absorbing light with a wavelength around 1450nm. Since bruised areas have a relatively high water content and appear black in color, this wavelength can be used to photograph fruits for screening and classification.

Apple bruise detection

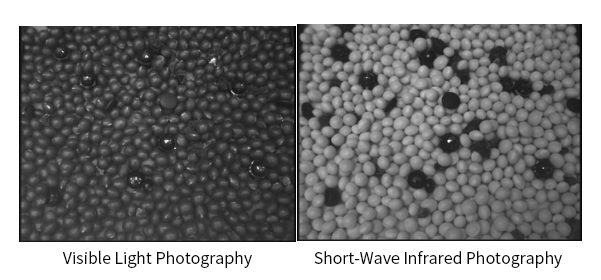

Foreign object detection:

Different substances have varying reflectivity and absorptivity for light of different wavelengths. Taking advantage of this property, even materials like plastics that appear identical to the naked eye can be sorted to select specific types.

Foreign object detection in black beans

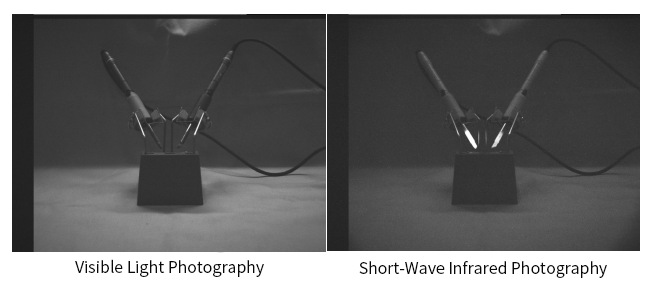

Temperature monitoring:

Image sensors can present heat in the form of brightness information, and SWIR image sensors can be used to observe objects with temperatures above 250°C.

Detection of the tip temperature of electric soldering irons

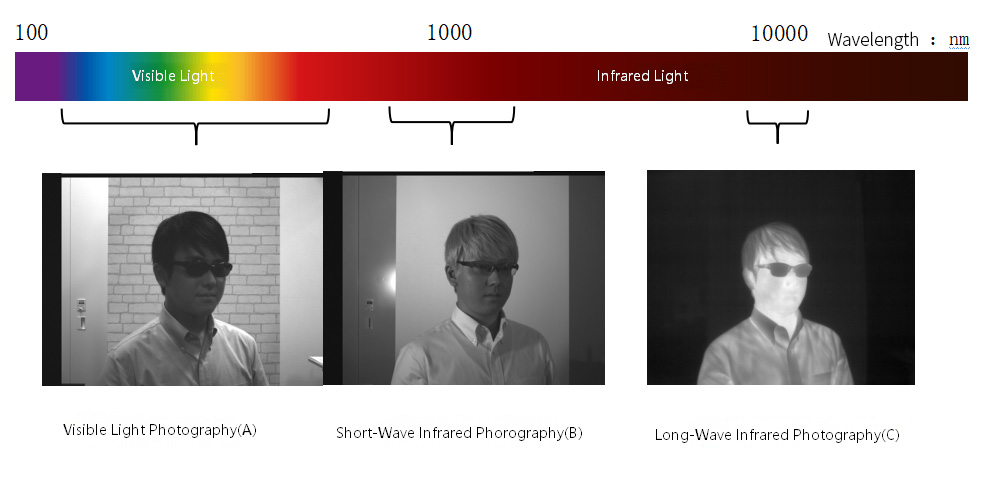

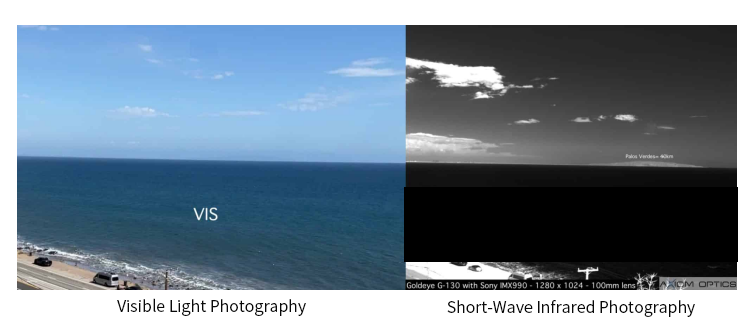

Visual enhancement:

Short-wave infrared imaging technology can easily capture short-wave infrared light that penetrates the sky. Compared with visible light imaging, images taken by short-wave infrared cameras exhibit higher visibility, allowing observation of farther and clearer target information.

Distant view shooting