Aspheric Bare Lenses

1、Choosing the Right Aspherical Lens

Aspherical lenses are often used to collimate the output light from an optical fiber or laser diode, to couple light into an optical fiber, to spatially filter the light, and to image the beam on a detector. This article introduces two applications of aspheric lenses, which will help customers choose the right aspheric lens.

1、Diode Collimation

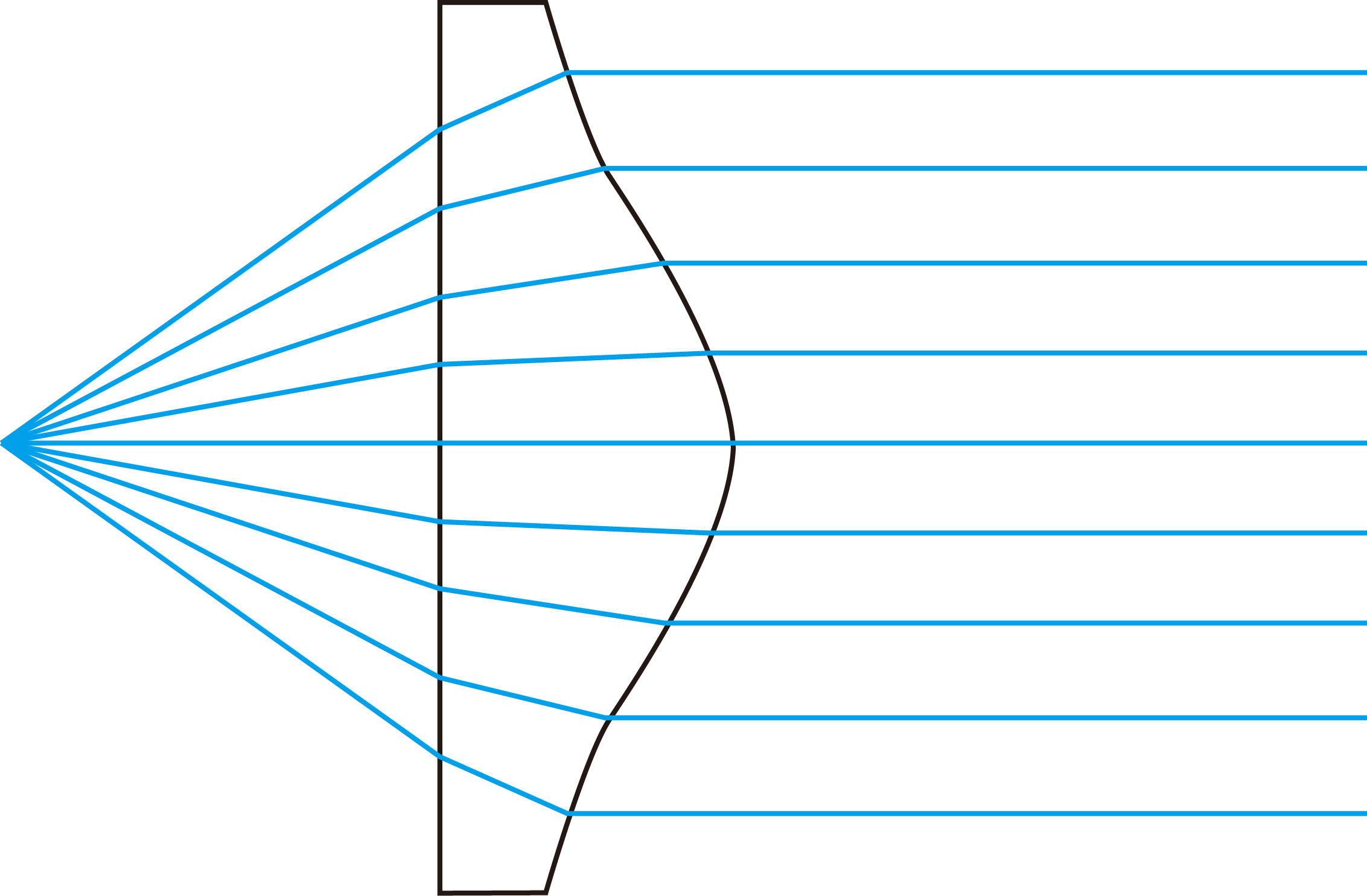

Due to the construction of the laser resonator cavity in the edge-emitting diode laser, the laser is emitted in an elliptical geometry with divergence. It is usually stipulated that the divergence is in the x-axis and y-axis respectively, the axis with large divergence is called the fast axis, and the axis with small divergence is called the slow axis. The output light of a laser diode is highly divergent and therefore requires the use of collimating optics, as shown in Figure 1.

Fig. 1 Aspherical lens laser collimation

When selecting an aspheric lens for collimating lasers, it is necessary to consider:

(1) Numerical aperture of the lens NA

Coupling a large number of lasers through the system requires the selection of an aspherical lens with a sufficiently large numerical aperture. Ideally, the numerical aperture of the lens should be larger than the numerical aperture of the fast axis of the laser, otherwise some light will be wasted.

Since the numerical aperture of the laser is defined in air, in most cases n = 1, i.e.

where θ is the half angle of the emission cone.

(2) The beam diameter D

Where EFL is the effective focal length of the lens and NA is the numerical aperture of the light source.

2、Fiber Coupling

Choosing the right aspheric lens to couple the laser into the fiber is important to maintain the high efficiency of the optical system.

When selecting a lens to focus light into an optical fiber, the focal length of the lens first needs to be considered. From the equation above, we can obtain that

Where NA is the numerical aperture of the fiber used for coupling. The EFL calculated in the above equation is the minimum EFL required to fully couple the light into the fiber.If a lens with a longer EFL is used, then the spot at the tip of the fiber will be larger, so it is preferable to use a lens with the shortest possible EFL and which has an EFL greater than the minimum value specified above.

2、Manufacturing Process

1、Precision glass molding

Precision glass molding involves heating an optical glass core to a high temperature so that its surface is sufficiently malleable to be shaped through an aspheric mold, and then gradually cooling it to room temperature, where the optical glass core will still retain the shape of the mold. There is a high initial cost to manufacture the mold, but when the mold is complete, the incremental cost per aspheric lens is lower than standard manufacturing techniques, making this manufacturing technique particularly suitable for high volume production.

2、Precision Polishing

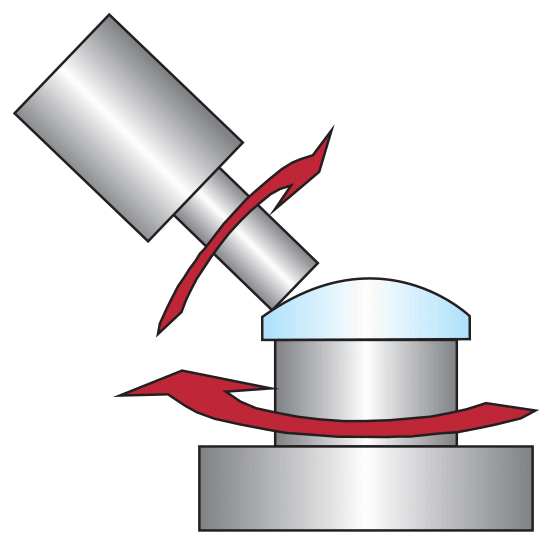

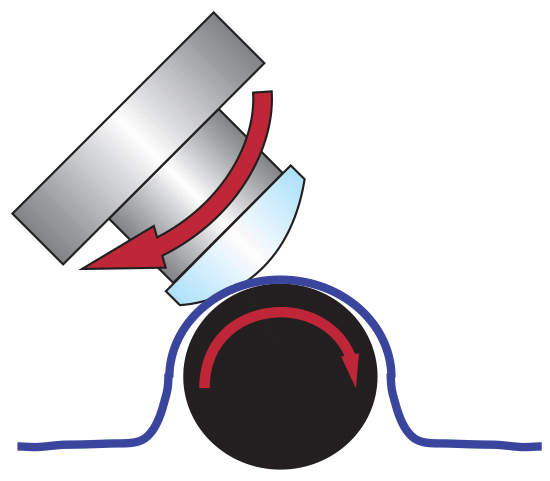

Aspheric lenses are machine processed by grinding and polishing one by one. While the process of manufacturing aspheric lenses one by one has not changed dramatically, advances in manufacturing technology have increased the highest level of precision achievable with this manufacturing technique. Computer-controlled precision polishing automatically adjusts the tool dwell parameters to accurately form the aspherical shape, as shown in Figure 2. When higher polishing quality is required, magnetorheological polishing (MRF) can be used, as shown in Figure 3. MRF technology provides precise control of the removal position and high removal rates, enabling high performance polishing in a shorter period of time than standard polishing techniques. While other manufacturing techniques require costly tooling, polishing uses standard tools, making it the preferred choice for prototyping and low-volume production.

Figure 2 Computer-controlled polishing

Figure 3 Magnetorheological polishing

3、Hybrid Molding

A standard spherical surface of an achromatic lens is used as a substrate to produce an aspherical surface by die casting that spherical surface through an aspherical mold containing a photosensitive polymer. This technology uses a diamond-frosted aspheric mold and a glass achromatic lens, injects the photosensitive polymer into the aspheric mold, and then allows the aspheric mold to die-cast the spherical surface. Finally, this technique forms an aspheric achromatic lens by compressing and UV curing both surfaces at room temperature. The lens achieves both achromatic and spherical aberration correction. Hybrid molding is suitable for high-volume, high-precision applications where, in addition to the need for extremely high performance, its high initial tooling cost can be offset by the cost savings gained from mass production.

4、Plastic Injection Molding

Plastic injection molding involves the injection of molten plastic into an aspherical mold. Compared to glass, plastics are less thermally stable and less resistant to pressure, and therefore require special treatment to obtain equivalent aspheric lenses. However, plastics have the advantages of low cost, light weight, and ease of molding, and are widely used for applications with moderate optical quality, insensitive thermal stability, and modest pressure resistance.

| Type | Dominance |

| Precision glass molding | Suitable for large batch sizes, high quality and high thermal stability |

| Precision Polishing | Short prototyping cycle and no need for molds, suitable for small batch production. |

| Hybrid Molding | Features spherical aberration and achromatic aberration correction for wide spectrum, large batch size and high quality |

| Injection Molding |

Suitable for large batch sizes, moderate quality and low thermal stability |